In July 2017, Kemin received customer demand for a foldable jam box production system. After a professional team of R & D design, precision production and assembly commissioning, in November of the same year, the customer personally visited the Koming factory acceptance, acmeplas successfully delivered this intelligent production system.

For two years, the production of this system in Indonesia factory is stable, each time regular return visit has been confirmed and praised by customers.

In-mold labeling box intelligent production system-folding jam box

Injection molding machine: Burstein S-TECH 2800KPS

Mould: M17029 heat flow

Channel: Husky manipulator: ACME-CH (labeling machine)

Back end: adaptive acmeplas automatic Packer

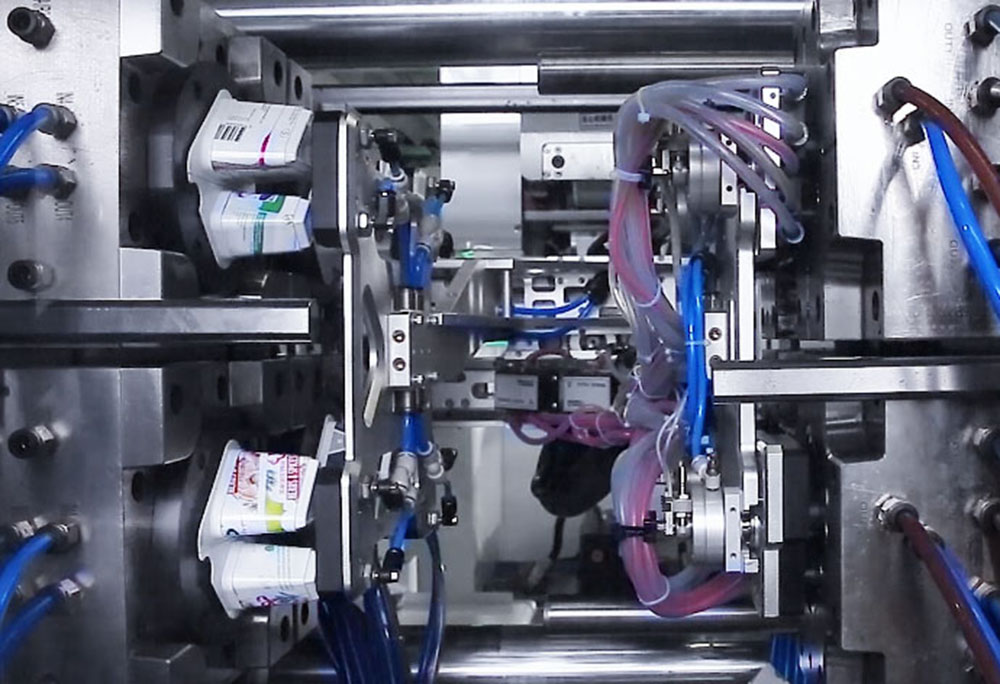

Mold opening cavity after injection Molding

Pick up the label and place the sucked paper on the sticker

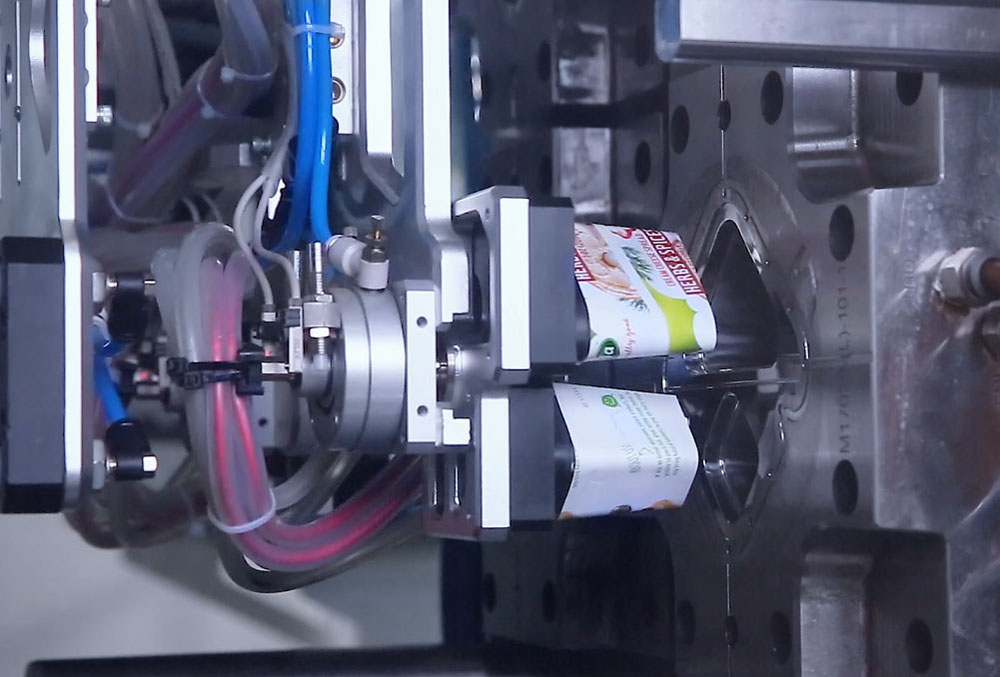

The labeling machine puts the label paper into the mold cavity

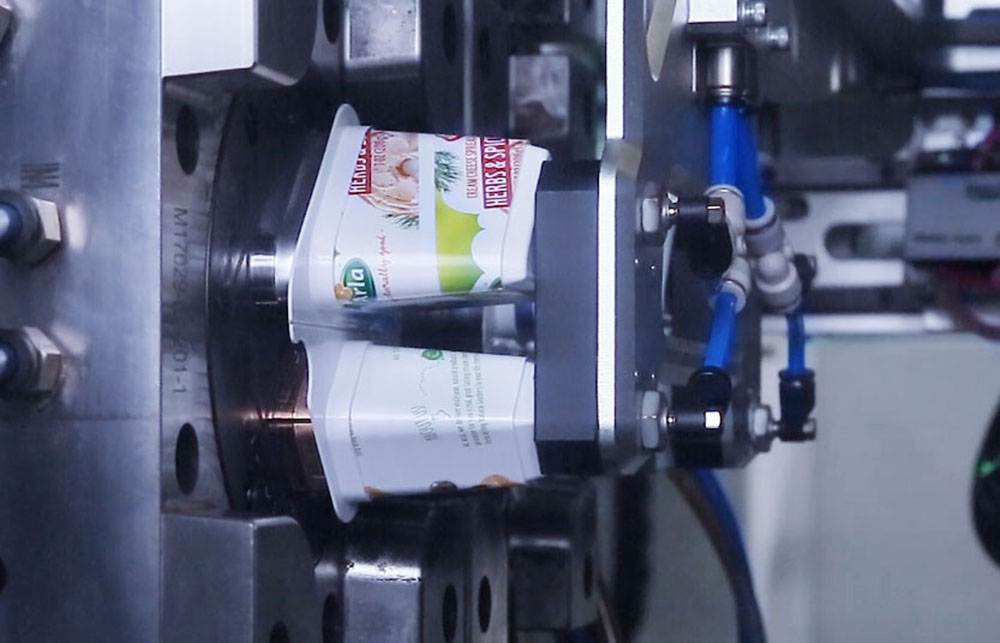

Injection molding mechanical arm taking-out product

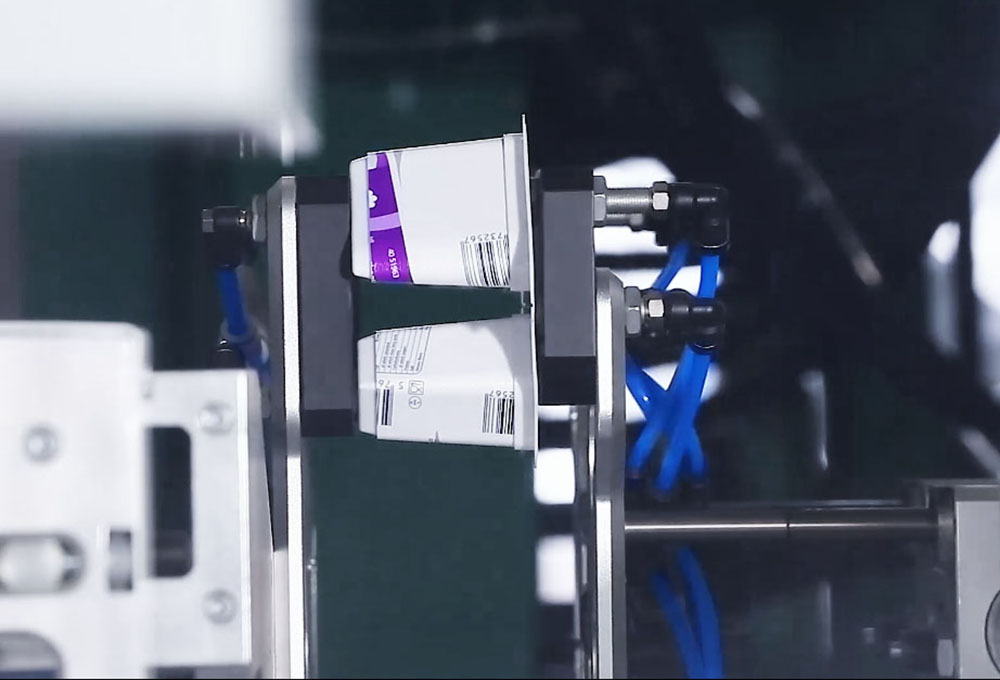

The manipulator is taken out of the product, and the product is transmitted to the stacking mechanism

The stacking mechanism places the product on the conveyor belt

The system can be realized from the incoming to the package, the full automatic production, the no-hand contact, the production period of 9.6 s when delivered two years ago, and is now within 8s.